Computer Numerical Control (CNC) A type of machining, has revolutionized manufacturing and engineering in recent years. By integrating digital technology into traditional machine tools, CNC machining has emerged as a predominant method for creating high-precision pieces and components across a range of industries. This article explores the mechanics, benefits, and diverse applications of CNC Machining, highlighting its transformative impact on the field of modern engineering.

The Mechanics of CNC Machining

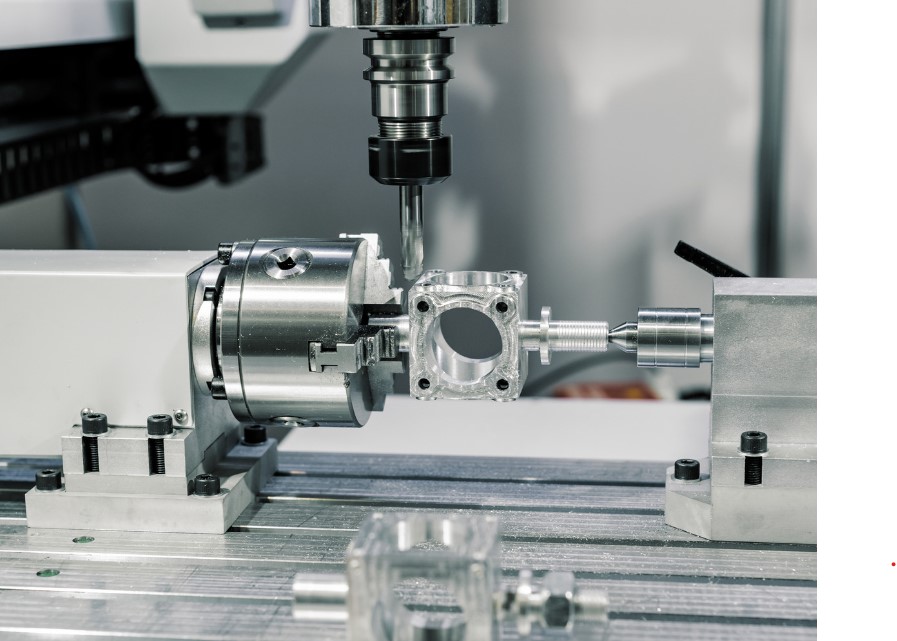

CNC machining is a subtractive method of manufacturing in which the material is removed from a solid block, or workpiece, to create the desired shape. This process is guided by computer software that has been pre-programmed and regulates the actions of the machine. The code generated by CNC machines is dependent on the type of machine used as well as the complexity of the item. But, the principle is the same: High-speed cutters precisely cut away materials to produce the final product.

Precision is one of the major benefits of CNC machine. Digitalization can ensure extremely precise and constant production. This helps reduce errors made by humans, and also ensures uniformity between batches. This level of precision is vital in industries where even the slightest deviation can have major consequences, such as aerospace, medical devices, and automotive manufacturing.

The role of digitalised computer systems in CNC machine operation

Digital technology is at the heart of CNC machine’s effectiveness and precision. CNC machines are controlled using specific software that automatizes every step of manufacturing. This software converts computer-aided design (CAD) models into a series of precise instructions, which the CNC machine then follows to create the part. These instructions describe everything from the cut depth and the angle to the speed of the tool.

In large-scale industrial plants, computers are usually integrated directly into CNC machines. This permits seamless communication and controls. This integration allows real-time monitoring, which ensures high performance and minimizes the amount of downtime. CNC machine machining can be automated to facilitate continuous operations, increasing productivity and reducing lead times.

CNC Machining Advantages

CNC machining comes with numerous benefits over traditional manufacturing methods. Its capability to make intricate and complex parts with high accuracy is one of the biggest benefits. CNC machining is accurate which eliminates the need to make manual adjustments or rework. This reduces wasted time and boosts efficiency. Furthermore, CNC machines can operate constantly, which makes them ideal for production runs that are large in volume.

Another benefit is the flexibility of CNC processing. One machine can make various types of components by simply changing the program. CNC machine is able to be modified and is suitable for prototyping as well in mass production. This allows manufacturers to quickly respond to market demands changes.

Automating CNC machining increases safety at work. Because it reduces the need for manual intervention, the chance of injuries and accidents is diminished. Furthermore, the constant quality of CNC-machined parts enhances product durability and efficiency, contributing to the satisfaction of customers and brand reputation.

CNC Machining Services Benefits for Industries

In a variety of industries CNC machining has proved to be extremely efficient as well as precise and flexible. In the aerospace industry, CNC machines produce critical components that must meet stringent safety and performance standards. CNC machines are employed in the medical device industry to make complex surgical instruments and implant devices, in which precision is essential.

The automotive industry makes use of CNC milling to make engine parts, transmission components as well as intricate exterior and interior features. Similar to electronics, the industry gets benefit from CNC machine’s capability to create small, precise components that are used in consumer electronics and communication devices. The art and jewelry industries as well utilize CNC technology to produce custom pieces and intricate designs.

The future of CNC Machining

CNC capabilities for machining are anticipated to increase as technology advances. CNC’s capabilities will further be enhanced by technological advancements like multi-axis machines additive manufacturing, advanced materials. Machine learning and artificial intelligence will likely improve the efficiency and precision of CNC machine machining.

In the end, CNC machining has profoundly revolutionized manufacturing and engineering and manufacturing, delivering unparalleled accuracy, efficiency, and flexibility. Its ability to produce complex components with high accuracy makes it an indispensable instrument across a range of industries. CNC is machining, even as the technology develops will be an integral component in manufacturing’s future.